Project

DuPont Tower

Modular upgrade improves plant efficiency

Location

Wilmington, DE

Project Type

Industrial Cooling

Project Scope

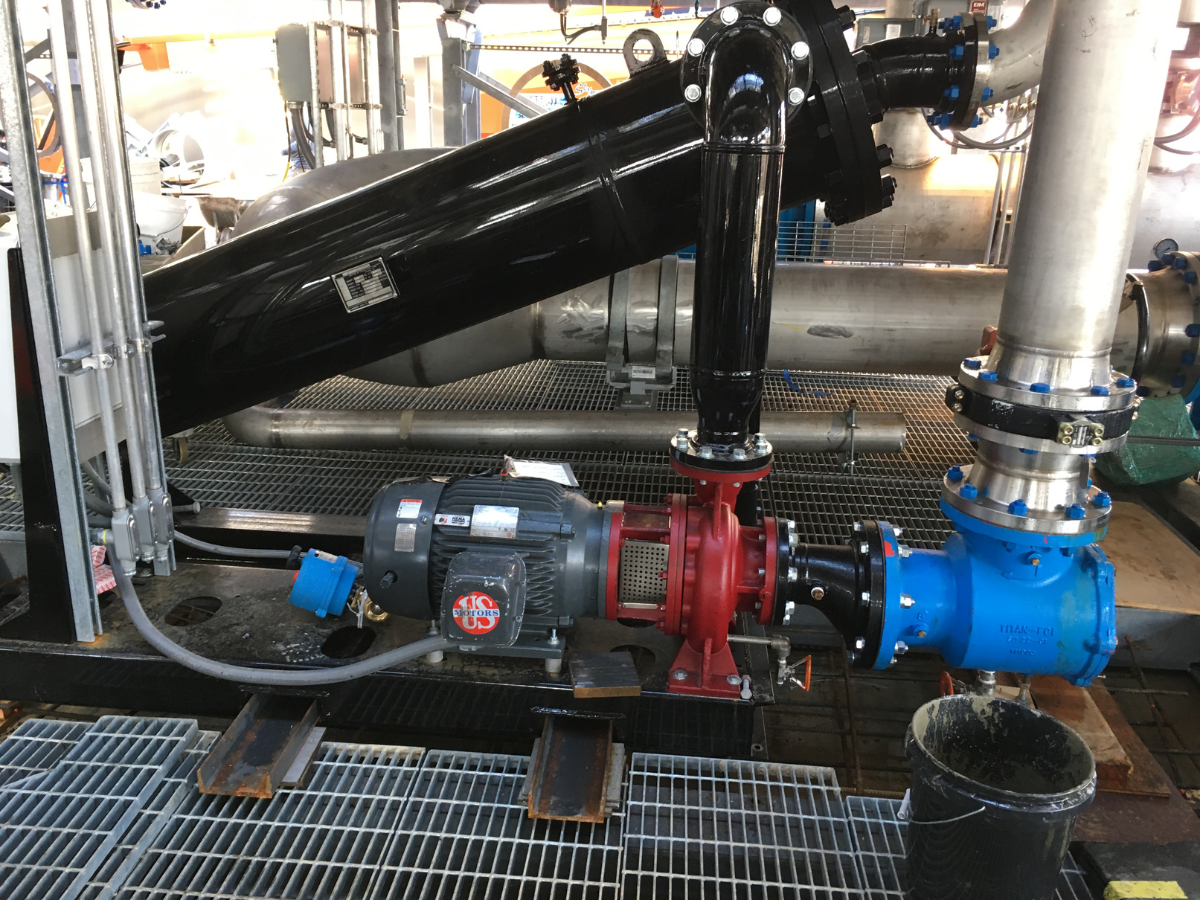

ETS supported DuPont’s replacement of a 63-year-old cooling tower at its 15,000-ton refrigeration plant. The new 10,000-ton modular cooling tower was built in the original footprint and completed in just 8 months to minimize downtime.

Legacy Infrastructure

The challenge was replacing a 1956 cooling tower that supplied 6,000 tons of condenser water—without disrupting operations. Space and time constraints demanded a creative approach. ETS worked with partners to design modular skids that fit the existing footprint, allowing for swift and precise installation using air skids and prefabricated electrical controls.

Fast, Precise Installation

To meet the tight 8-month deadline, ETS used Revit for coordination and oversaw off-site fabrication. Each modular unit was built, wired, and tested before delivery. This reduced on-site labor and eliminated the need for temporary cooling equipment, saving time and cost.

"ETS helped us replace decades-old infrastructure without interrupting operations. Their planning and execution were spot-on."

Faster, Smarter, Stronger

The DuPont cooling tower replacement was completed in just 8 months. With four-cell segmentation and variable speed drives, the new tower delivers efficient, quiet performance year-round. ETS’s modular approach eliminated the need for temporary cooling, saving significant costs and minimizing disruption to ongoing operations.

Completion time

Tons of cooling capacity

VFD-controlled fans

Days of plant shutdown

Bring Smart Cooling to Your Facility

Need to upgrade critical infrastructure without interrupting operations? Learn how ETS can help you design and install modular systems on time and on budget.